From idea to

prototype

Our strength is to be able to interpret each brand we produce, we have the sensitivity to create through details and finishes products that are very different from each other but that reflect the profound essence of each brand that relies on our many years of experience.

From idea to

prototype

Our strength is to be able to interpret each brand we produce, we have the sensitivity to create through details and finishes products that are very different from each other but that reflect the profound essence of each brand that relies on our many years of experience.

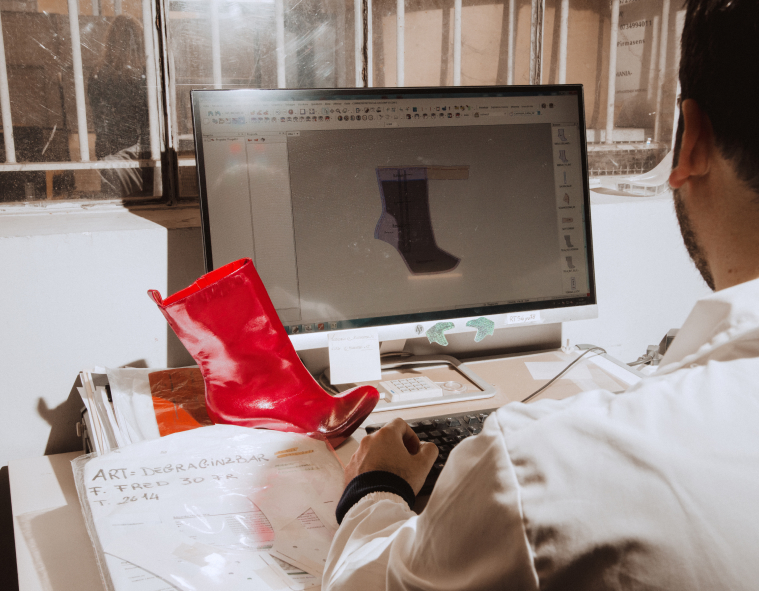

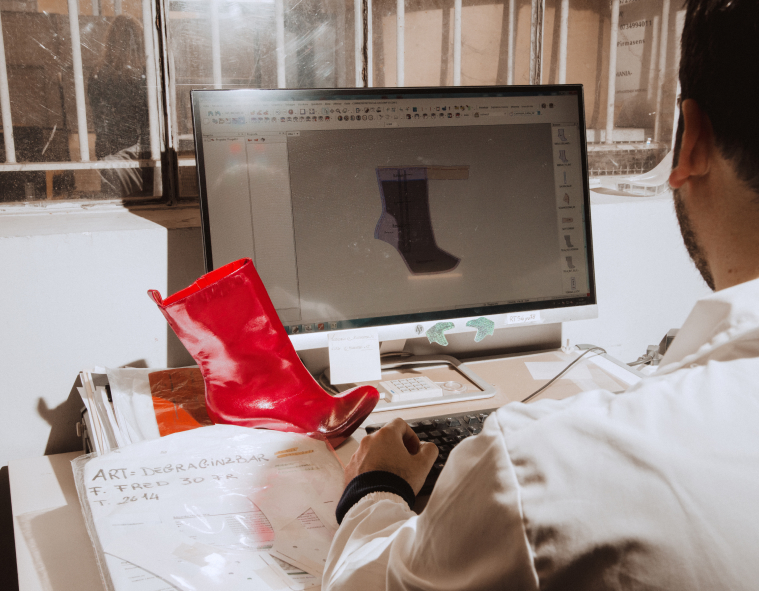

Following receipt of the designer’s draft, the pattern-making department takes care of interpreting it and transforming it into a paper and digital technical drawing, then developing the prototype. At the same time, the study of the various components is started, producing accessories of the highest quality to enhance their uniqueness.

Three

production

handlines

The Arktè shoe factory has three production lines. This means that the company has organised its production process into three separate streams to create different types of footwear or manage various production stages. This subdivision allows the company to optimise efficiency and resource management, improving overall productivity.

Three

production

handlines

The Arktè shoe factory has three production lines. This means that the company has organised its production process into three separate streams to create different types of footwear or manage various production stages. This subdivision allows the company to optimise efficiency and resource management, improving overall productivity.

A 360° Tailor Made

service

A 360°

Tailor Made

service

Modeling

Arktè coniuga la capacità di Arktè combines the ability to create individual models using the most advanced CAD-CAM systems and the manual and interpretative skills necessary to create the most complex models that lead to the birth of a masterpiece.

Sampling

Following the creation of the prototype and its presentation to the client, after careful fitting and line verification, the production of samples for presentation in different global markets proceeds.

Leather Warehouse

Working with different brands with strong identities inevitably leads to the need to manage thousands of references and often limited quantities of raw materials and components. Even in the leather warehouse, Arktè employs skilled workers who can combine artisanal spirit with the needs of the production lines.

Cutting

Once the industrialisation process has started, the first step is to cut the materials, whether leather or other, manually or automatically

Edging

After cutting the materials, it is necessary to edge the upper to start the assembly process. Skilled edgers take care of this delicate process.

Production

During the industrialization phase of the product, a highly specialized staff oversees the main processing phases and various steps that lead to the final definition of the footwear: from cutting the leathers, to working them, to finishing and quality control.

Special Projects

Arktè is entrusted with special projects ranging from the creation of a single model for an extraordinary event (such as the Oscars ceremony) to collections to be used during the world’s most exclusive fashion shows.

Assembly

Following the edge finishing, the uppers are prepared and inserted into the assembly line in order to be assembled with various components.

Finishing

After assembly, all shoes are carefully finished, cleaned and prepared for final inspection, one by one.

Quality Control

The entire finished product is individually inspected by the quality control team in order to approve it or not according to the very strict quality standards required by the client.

Packaging

The packaging is handcrafted with particular attention to the protection that each shoe must-have during the inevitable movements that will follow. An essential aspect is an emotionally impactful result that must be obtained upon opening the packaging.

Logistics

Another asset of Arktè is the logistics process carried out using electronic means, which allows for timely delivery and precision in deliveries.

Modeling

Arktè coniuga la capacità di Arktè combines the ability to create individual models using the most advanced CAD-CAM systems and the manual and interpretative skills necessary to create the most complex models that lead to the birth of a masterpiece.

Sampling

Following the creation of the prototype and its presentation to the client, after careful fitting and line verification, the production of samples for presentation in different global markets proceeds.

Leather Warehouse

Working with different brands with strong identities inevitably leads to the need to manage thousands of references and often limited quantities of raw materials and components. Even in the leather warehouse, Arktè employs skilled workers who can combine artisanal spirit with the needs of the production lines.

Cutting

Once the industrialisation process has started, the first step is to cut the materials, whether leather or other, manually or automatically

Edging

After cutting the materials, it is necessary to edge the upper to start the assembly process. Skilled edgers take care of this delicate process.

Production

During the industrialization phase of the product, a highly specialized staff oversees the main processing phases and various steps that lead to the final definition of the footwear: from cutting the leathers, to working them, to finishing and quality control.

Special Projects

Arktè is entrusted with special projects ranging from the creation of a single model for an extraordinary event (such as the Oscars ceremony) to collections to be used during the world’s most exclusive fashion shows.

Assembly

Following the edge finishing, the uppers are prepared and inserted into the assembly line in order to be assembled with various components.

Finishing

After assembly, all shoes are carefully finished, cleaned and prepared for final inspection, one by one.

Quality Control

The entire finished product is individually inspected by the quality control team in order to approve it or not according to the very strict quality standards required by the client.

Packaging

The packaging is handcrafted with particular attention to the protection that each shoe must-have during the inevitable movements that will follow. An essential aspect is an emotionally impactful result that must be obtained upon opening the packaging.

Logistics

Another asset of Arktè is the logistics process carried out using electronic means, which allows for timely delivery and precision in deliveries.

“Technology 4.0”

The competitiveness of a luxury company must undoubtedly be based on high-level manufacturing capabilities and, at the same time, progress through the use of the most advanced technologies available. Arktè has introduced industrial processes based on the most advanced 4.0 technology used daily in advancing production phases.

“Technology 4.0”

The competitiveness of a luxury company must undoubtedly be based on high-level manufacturing capabilities and, at the same time, progress through the use of the most advanced technologies available. Arktè has introduced industrial processes based on the most advanced 4.0 technology used daily in advancing production phases.